Biology built the world. Now we’re upgrading its hardware.

Biology could ultimately produce or replace up to 60% of the materials that power the global economy*

* McKinsey and Company

The Biorevolution: Innovations transforming Economies, Societies and our Lives

To harness biology, we need to recreate the environment bacteria evolved in.

Temperature. pH. Nutrients. Oxygen. Sterility. Precision

We do that in a bioreactor.

Traditional bioprocessing is hard: crippling upfront costs, months of waiting for equipment, and then biology that gave a perfect yield at 1L fails when you scale.

Our model is different.

With Chainreactor, your quarterly subscription lets you prove your biology at 1L, simulate at 10kL, then scale at our bioprocessing facility. The system and biology don’t change. Only the volume does.

And in 2026, we’re offering our first 100 bioreactors for free. Try Chainreactor in your workflow and let the results speak for themselves.

KEY FEATURES

OUR REACTORS

1

2 - 2000 liters

One easy subscription

Desktop / Cloud Control / Scriptable / Iterative

VESSELS

2

Polymer vessel sizes from 250ml to 2k liters

Stirred tank, Airlift and Perfusion Bioreactors

Machine vision soft sensors

CONTROL SYSTEM

3

Peristaltic pumps

Cascade control

Heating and cooling system included

Standard sensors: PH, DO, Temperature

Agitation Control

Touchscreen Interface

Fully scriptable processes

BACKED BY

Chainreactor is building the picks and shovels for the biotech revolution

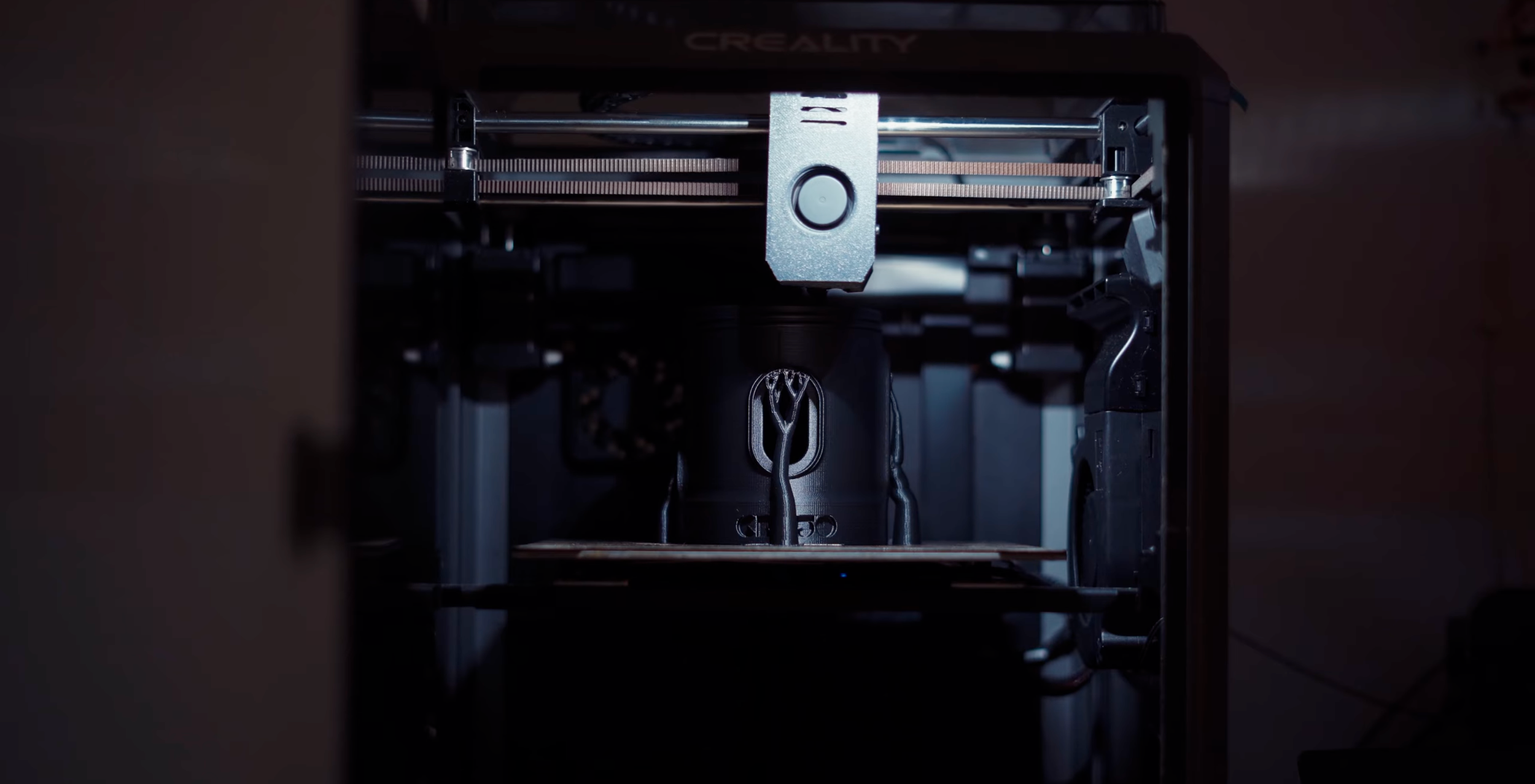

Based in Lisbon, Portugal, our founding team has extensive experience in biotechnology and additive manufacturing, and includes the founders of two successful startups.

Blending hands-on production capabilities and advanced automation skills, we’re driven by the determination to help solve some of humanity’s most complex problems. One bioreactor at a time.